Your cart is currently empty!

Rubber Band Car Tips: Powering Your Projects with Potential Energy

Rubber Band Car Tips are essential for anyone looking to build a fast, efficient, and fun vehicle powered by potential energy. Whether you’re a student tackling a science project, a hobbyist exploring engineering concepts, or just someone looking for a creative challenge, understanding how to maximize the power of rubber bands can make all the difference. From selecting the right rubber bands to optimizing the car’s design, this article will equip you with the knowledge to transform simple materials into a high-performance machine.

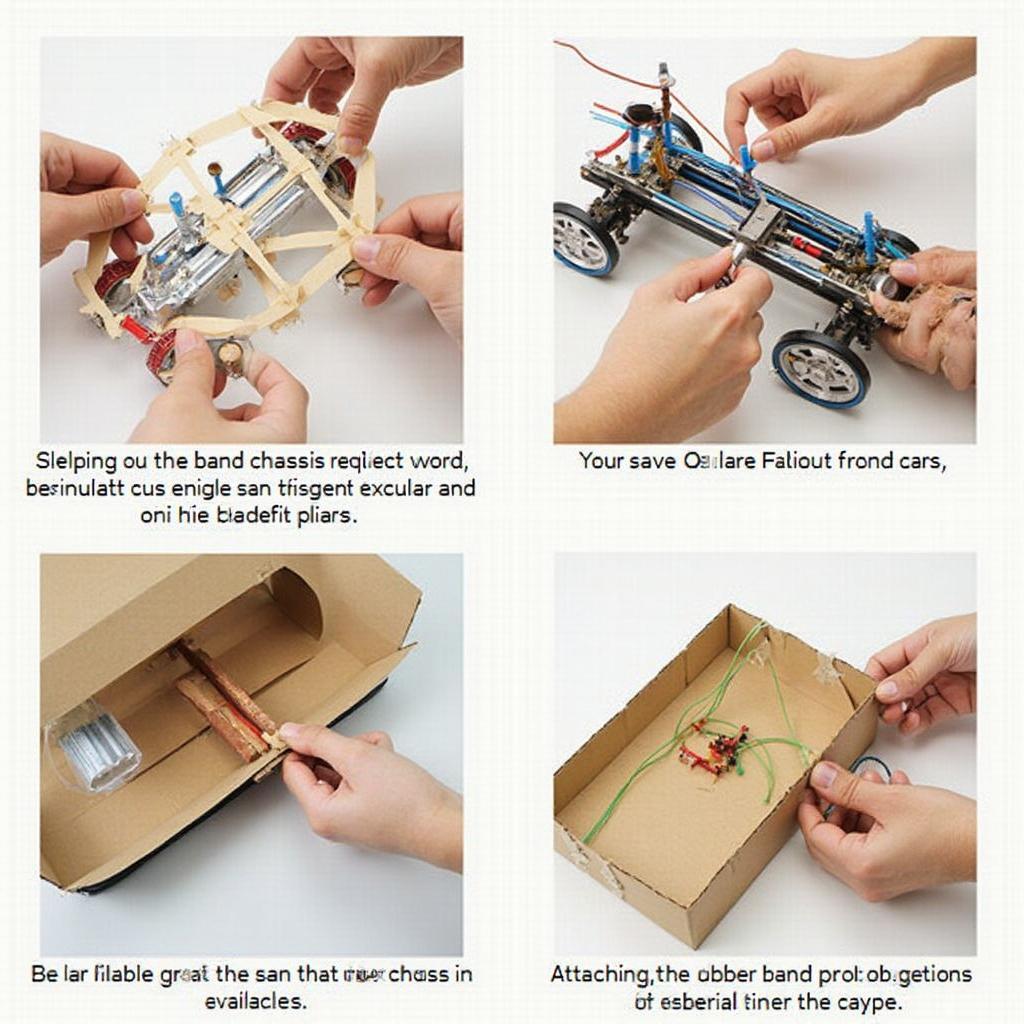

Rubber Band Car Construction

Rubber Band Car Construction

Choosing the Right Rubber Bands for Your Car

Not all rubber bands are created equal. The type of rubber band you choose significantly impacts your car’s performance. Thicker rubber bands generally store more energy, resulting in a more powerful launch. However, they can also be harder to wind and may require a more robust car design. Experimenting with different sizes and thicknesses is key to finding the optimal balance between power and practicality. Consider using multiple thinner rubber bands in parallel to achieve a similar effect to a single thicker one, reducing stress on the winding mechanism. For smaller cars, thinner, more pliable rubber bands might be a better choice, allowing for easier winding and a smoother ride.

Understanding the Science Behind Rubber Band Power

Rubber bands store potential energy when stretched. This energy is then converted into kinetic energy, the energy of motion, when the rubber band is released, propelling the car forward. The amount of energy stored depends on the rubber band’s size, thickness, and the material it’s made from. Maximizing this stored energy is crucial for achieving optimal car performance.

If you are looking for tips on a different type of car, check out these driving tips for cvt cars.

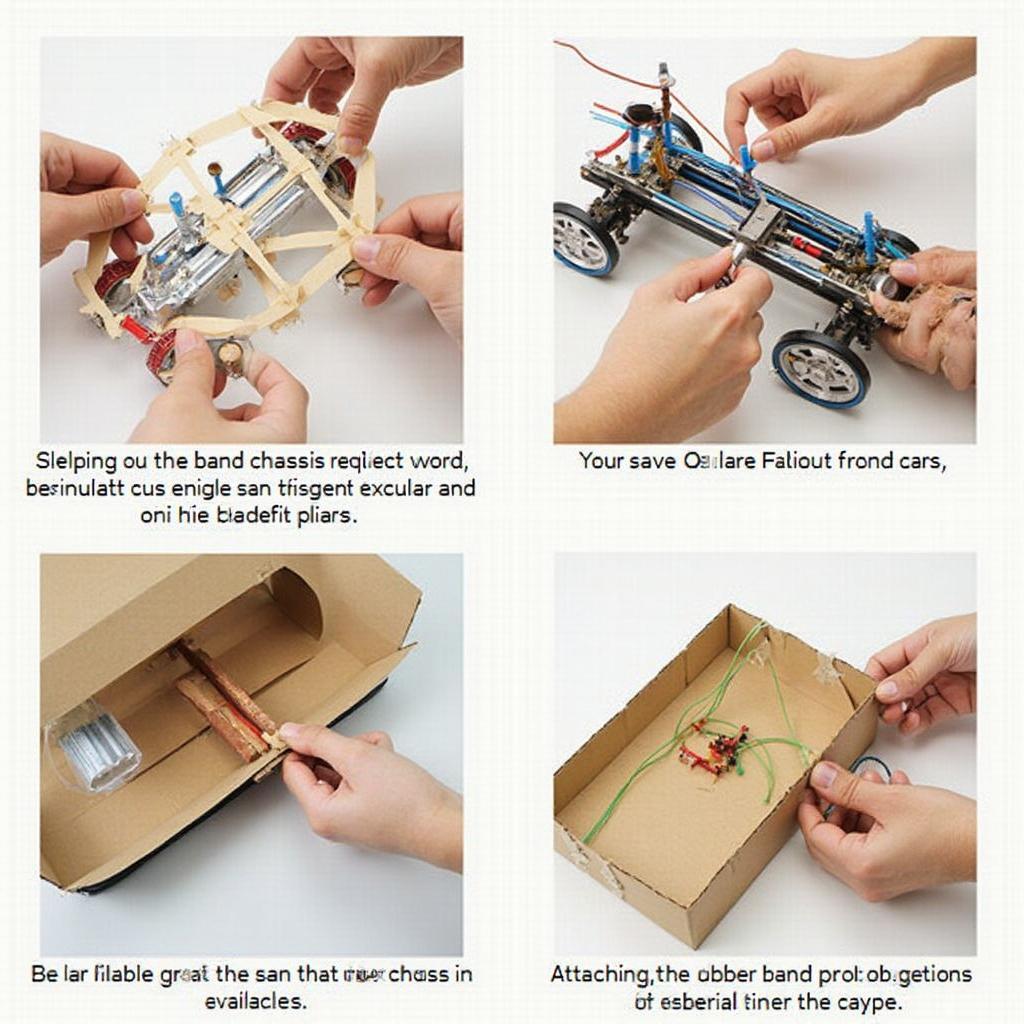

Optimizing Your Car’s Design for Maximum Speed

The car’s design plays a critical role in how effectively the rubber band’s potential energy is converted into motion. A lightweight chassis with minimal friction is essential for achieving maximum speed. Consider using materials like balsa wood or lightweight plastic for the body. Aerodynamics also play a role, so a streamlined design can help reduce air resistance. The wheels should be lightweight and spin freely on their axles, minimizing friction. Proper alignment and secure attachment of the axles are crucial for efficient power transfer.

Building a Sturdy and Efficient Chassis

A sturdy chassis is essential for a successful rubber band car. It provides a stable platform for the wheels and the rubber band mechanism. Ensure all components are securely attached to prevent them from shifting or detaching during operation. A well-designed chassis will not only enhance the car’s performance but also contribute to its overall durability.

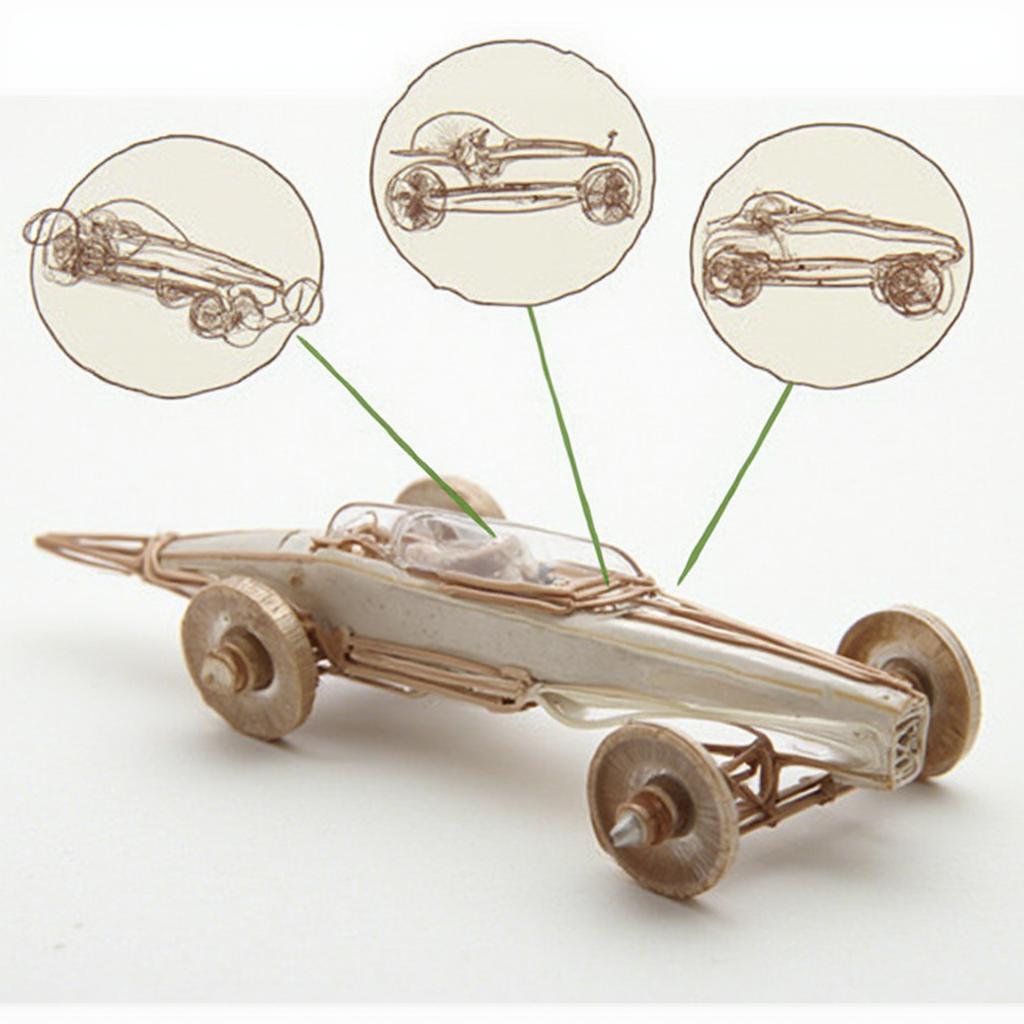

Aerodynamic Rubber Band Car Design

Aerodynamic Rubber Band Car Design

For enthusiasts interested in alternative propulsion methods, check out these balloon powered car tips. Maybe you are thinking of a mousetrap car? See mousetrap car top tips.

Winding Techniques and Launch Strategies

The way you wind the rubber band significantly affects the car’s performance. Overwinding can damage the rubber band or the car’s mechanism, while underwinding won’t provide enough power. Experiment with different winding techniques to find the sweet spot that maximizes power without causing damage. A smooth and consistent winding motion is key to achieving consistent results. The launch surface also plays a role. A smooth, flat surface is ideal for minimizing friction and ensuring a straight trajectory.

“Choosing the right rubber bands is as crucial as selecting the right tires for a real car,” says Dr. Amelia Gearheart, a renowned mechanical engineer specializing in kinetic energy systems. “The right rubber band matched with an efficient design can make all the difference in performance.”

Troubleshooting Common Rubber Band Car Problems

Sometimes, even with careful planning and construction, problems can arise. If your car isn’t performing as expected, check for common issues like excessive friction in the wheels, misaligned axles, or a poorly wound rubber band. Systematic troubleshooting can help identify and resolve these issues quickly.

“Remember, building a rubber band car is all about experimentation and iteration,” adds Dr. Gearheart. “Don’t be discouraged if your first attempt doesn’t break any speed records. Keep tweaking and refining your design, and you’ll be amazed at what you can achieve.” Perhaps you are looking for something different, like hair care tips for black toddlers.

Conclusion: Maximizing Your Rubber Band Car’s Potential

Building a successful rubber band car involves a combination of science, engineering, and a bit of creativity. By understanding the principles of potential energy, choosing the right materials, and optimizing your car’s design, you can create a high-performance machine that’s both fun to build and exciting to watch in action. So grab your rubber bands, gather your materials, and start experimenting with these rubber band Car Tips.

FAQ

- What type of rubber band is best for a rubber band car? Thicker rubber bands typically store more energy, but thinner ones are easier to wind. Experiment to find the best balance for your car.

- How can I make my rubber band car go faster? Reduce friction in the wheels and axles, use a lightweight chassis, and streamline the body for aerodynamics.

- How do I wind the rubber band without breaking it? Wind smoothly and consistently, and avoid overwinding. Test the limits of your rubber band to find the optimal winding point.

- What materials are best for building a rubber band car? Balsa wood, lightweight plastic, and cardboard are good options.

- What should I do if my rubber band car isn’t working? Check for friction in the wheels, misaligned axles, and ensure the rubber band is wound correctly.

Common Scenarios

- Scenario 1: The car veers off course. This is often caused by misaligned axles or uneven wheel sizes.

- Scenario 2: The car doesn’t travel far. This could be due to excessive friction, a poorly wound rubber band, or a heavy chassis.

- Scenario 3: The rubber band breaks frequently. Avoid overwinding and consider using multiple thinner rubber bands instead of a single thick one.

Further Exploration

For those interested in learning more about responsible car usage, check out tips for smoking weed in the car.

Need More Help?

For personalized support with your car diagnostics, reach out to our team via WhatsApp: +1(641)206-8880, Email: [email protected], or visit us at 456 Pine Avenue, Toronto, ON M5V 2J4, Canada. We’re available 24/7 to assist you.

Leave a Reply